Mitre Lock Bits

Mitre Lock Bits

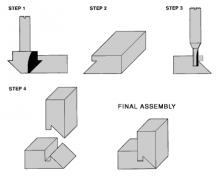

For some time the Mitre Lock Joint has been a problem to accurately produce consistently. The difficulty is making a square joint, because one panel has to be machined flat and the other panel must be cut in the possibly unstable vertical position. THIS PROBLEM IS NOW SOLVED! Both panels are now able to be machined on the flat - where maintenance of accuracy is assured. Note: it is recommended that a router table be used to assist in the accuracy of the cuts. ALL CUTS ARE PRODUCED WITH THE PANELS ON A HORIZONTAL POSITION. Instructions are supplied.

STEP 1. First 45º tongue is produced in Panel 'A' using Bit No. 1.

STEP 2. Second 45º tongue is produced in Panel 'B' using bit No. 1 also.

STEP 3. The Trench is produced in Panel 'B' with Bit No. 2. A strip of waste is produced.

STEP 4. Line up panel 'A' tongue with trench in Panel 'B' then join.

STEP 2. Second 45º tongue is produced in Panel 'B' using bit No. 1 also.

STEP 3. The Trench is produced in Panel 'B' with Bit No. 2. A strip of waste is produced.

STEP 4. Line up panel 'A' tongue with trench in Panel 'B' then join.

- Show All Shop Categories

- Routers Bits and Accessories

- Router Bits (Tungsten Tipped)

- Straight Router Bits

- Router Collet Extension

- Motorbody Building Bits

- Rounding Over Bits

- Ball Nose and Coving Bits

- Ogee Bits

- Classical Profile and Furniture Mouldings

- Chamfer and Angle Bits

- Dovetail, Angle Cutters and Vee Grooving

- Edge Radius Bits

- Moulding Bits and Inside Radius Bits

- Plinth Router Bits and Vee Grooving Bits

- Inverted Template & flush Trim Router Bits

- Profile and Furniture Moulding Bits

- Draw Pull and Combination Bits

- Nosing and Rebating Bits

- Classical Regency and Reeding Bits

- Mitre Lock Bits

- Profile Bits for Wardrobe Doors

- Profile Bits for Cupboard Doors

- Furniture Joining Bits

- Flush Trim & Template Following Bits

- Combination Laminate and Trimming Bits

- Edge Grooving Cutter

- Laminate Trimming and Beveling Bits

- Solid Surface Router Bits

- Solid Surface Kits

- Three Wing Moulding Cutters

- Weather Strip Grooving Router Bits

- Arbours and Bearing and Shim Spacers

- Compression and Spiral Router Bits

- HSS Aluminium Joinery Cutters

- Indexable Router Bits

- Indexable Blades

- Templates Accessories and Profile Cutterhead

- Router Bits (Tungsten Tipped)

LINBIDE

126 Captain Springs Road

Te Papapa, Auckland

New Zealand

PO Box 12-275, Auckland

Telephone 64-9-636 4121

Facsimile 64-9-636 8851

Email sales@linbide.co.nz

126 Captain Springs Road

Te Papapa, Auckland

New Zealand

PO Box 12-275, Auckland

Telephone 64-9-636 4121

Facsimile 64-9-636 8851

Email sales@linbide.co.nz